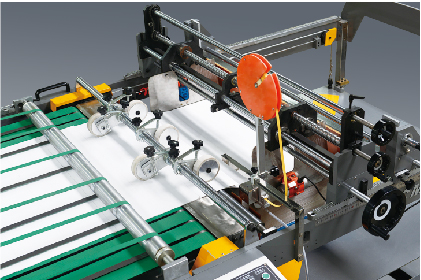

Features Introduced

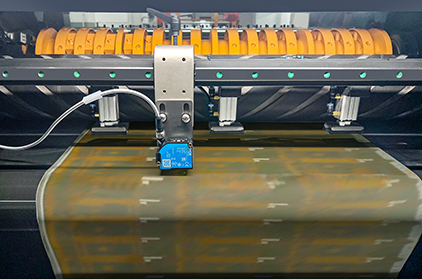

Based on the technology of SM series Servo precision Double-helix High Speed Sheet Cutter Machine,SMC series equipped with more intelligent function and better technological innovation.

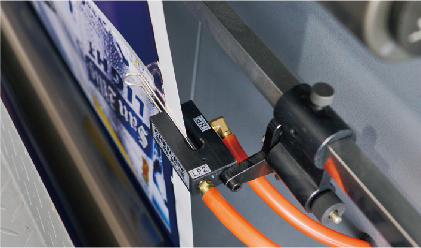

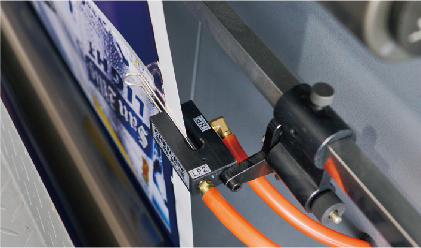

- Auto positioning slitting system.

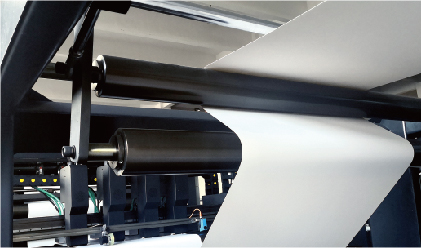

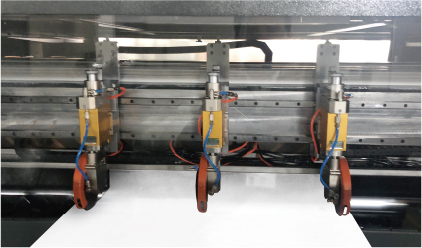

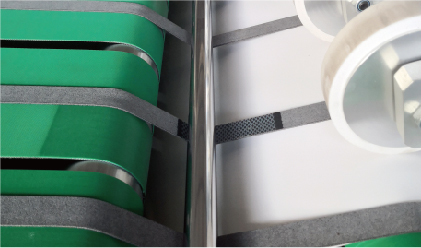

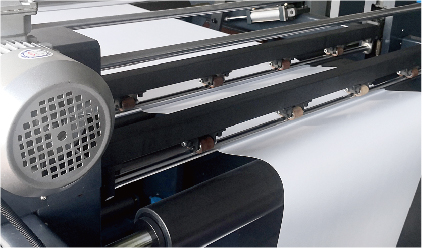

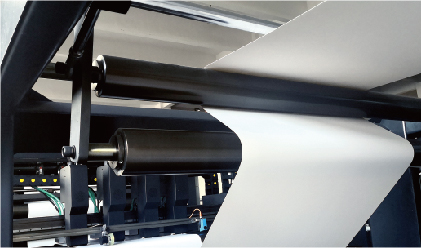

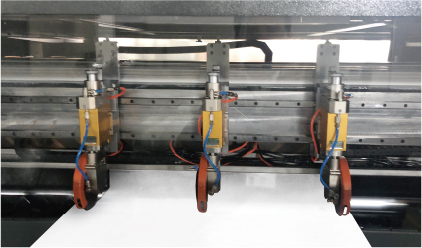

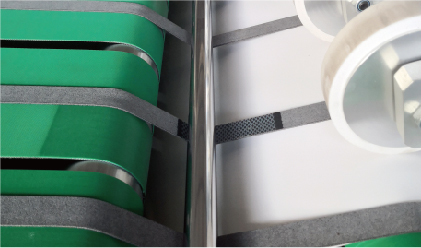

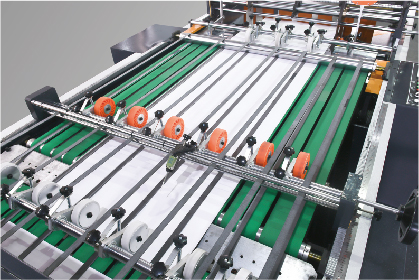

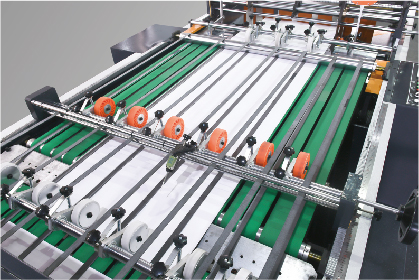

- Paper pre-press device.

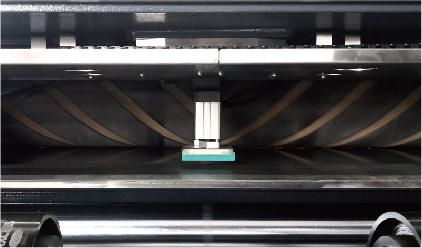

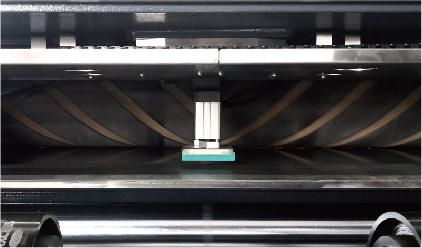

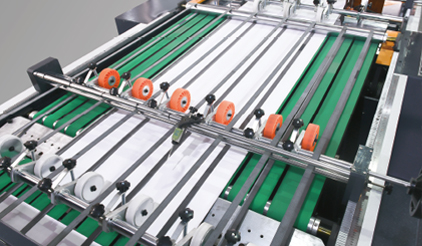

- 3 times delivery device(no impression line).

- Collecting board pneumatic lifting device.

Partial Introduction

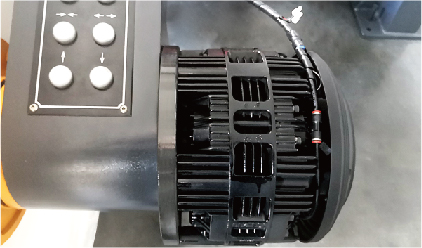

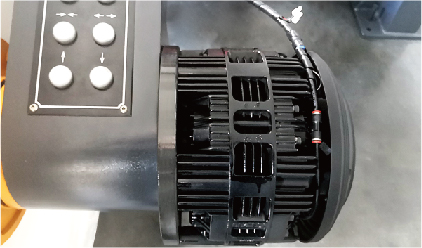

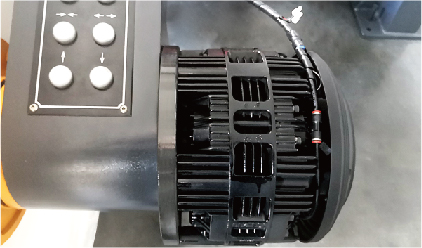

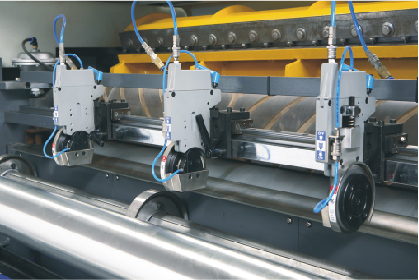

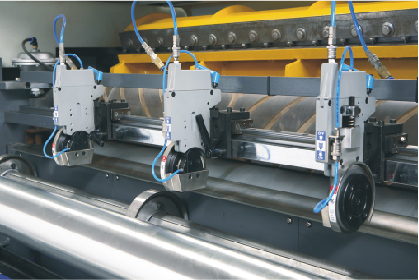

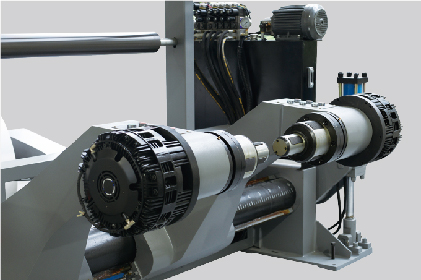

Auto brake

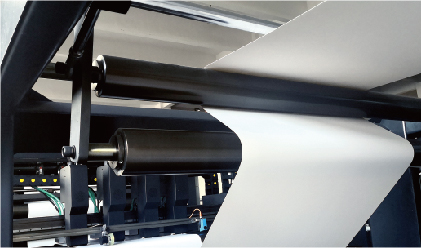

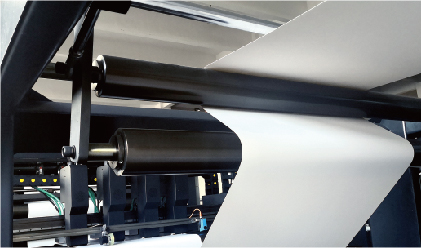

Auto anti curve

Auto tension control

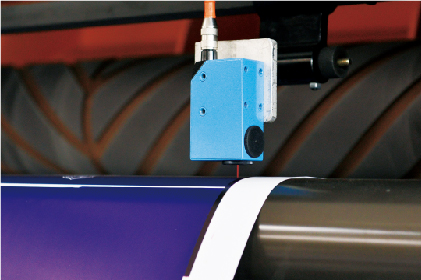

Auto edge position correction

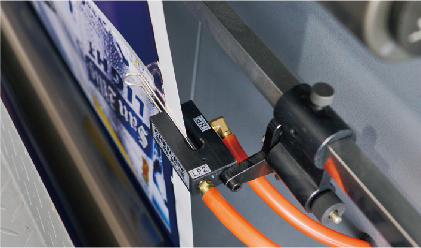

Auto positioning slitting system (optional)

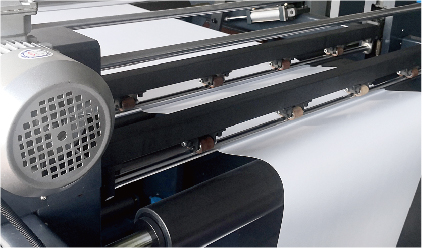

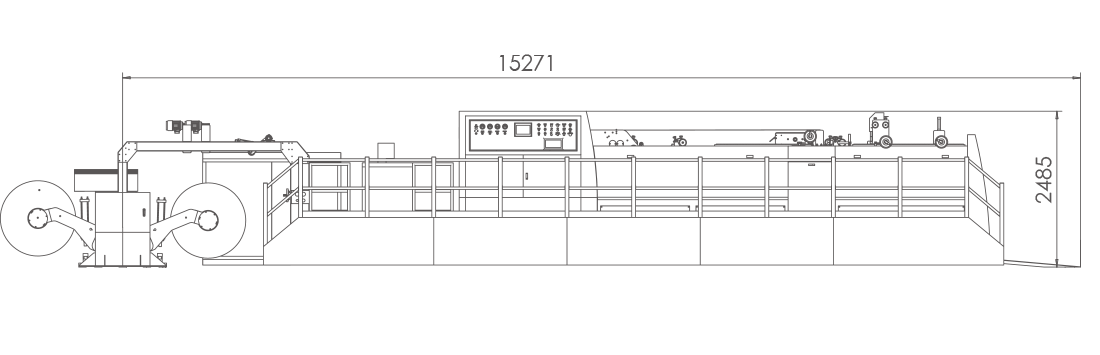

Paper pre-press device

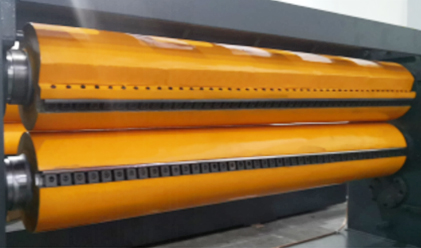

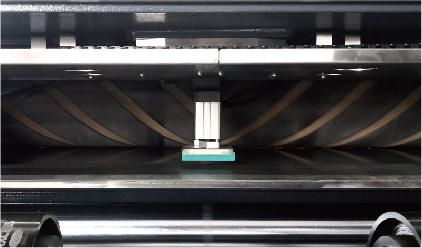

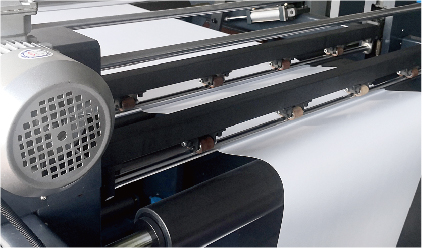

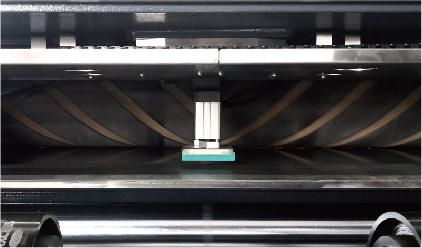

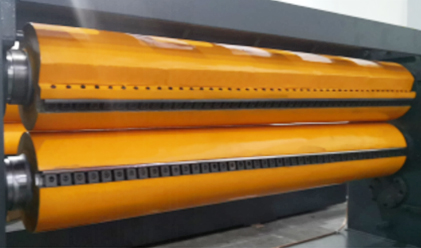

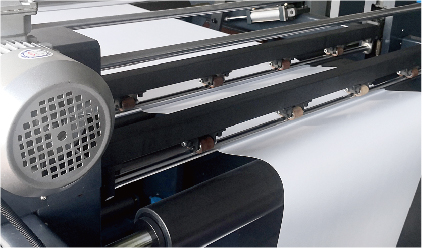

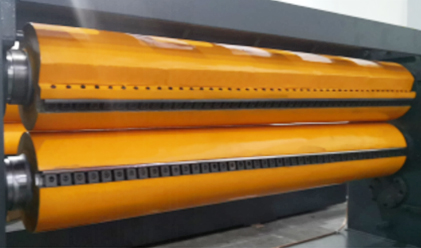

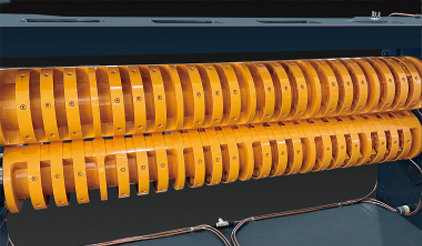

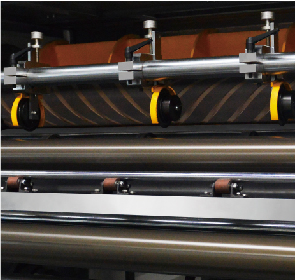

Double helix knife

Reject gate

Anti-static device

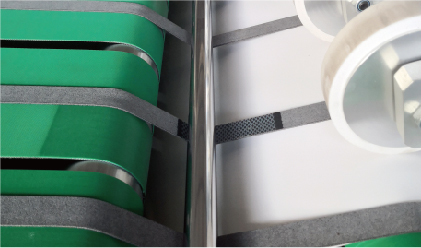

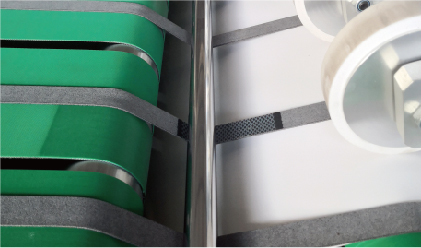

3 times delivery(no impression line)

Collecting board pneumatic lifting device

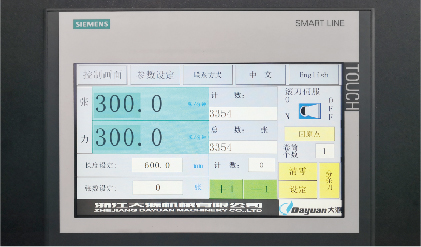

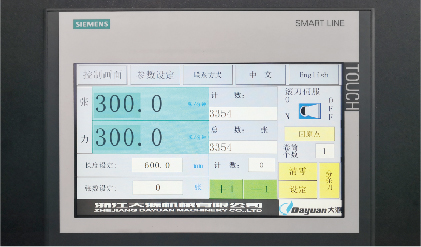

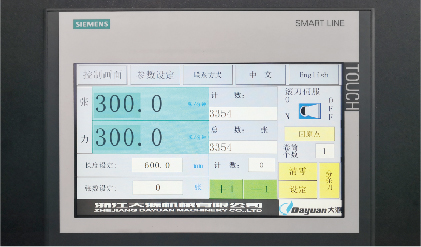

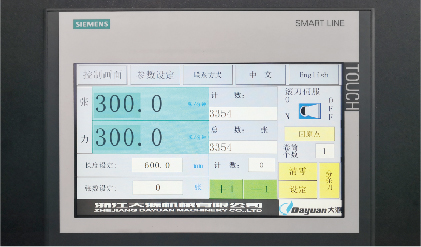

Siemens plc system

Main Technical Parameter

| Model | SMC-1100/1500/1700 |

| Model of cutting paper | Double rotary sheeter |

| Thickness of cutting paper | 100-1000gsm |

| Cutting length range | 450-1650mm |

| Cutting precision | Cutting length≤1000mm: ±0.1mm Cutting length>1000mm: ±0.1% |

| Max. cutting meter speed | 350 m/min |

| Max. cutting speed | 440 cuts/min |

| Max. scroll diameter | 1800mm |

| Max. paper cutting width | 1100(45”)mm 1500(59”)mm 1700(67”)mm |

| Max. paper piling height | 1600mm |

| The request for air compressor | 0.8Mpa |

| Power consumption | 380V/220VⅩ50Hz |

| Gross weight | 18000/20000/23000kgs |

| Full-load power | 69/82/90kw |

| Cutting Length(mm) | Speed(m/min) | Speed(cuts/min) |

| 450 | 125 | 275 |

| 500 | 160 | 315 |

| 550 | 190 | 350 |

| 600 | 210 | 350 |

| 650 | 250 | 380 |

| 700 | 290 | 410 |

| 750 | 330 | 440 |

| 800 | 330 | 410 |

| 850 | 330 | 385 |

| 900 | 330 | 365 |

| 950 | 330 | 350 |

| 1000 | 330 | 330 |

| 1050 | 320 | 300 |

| 1100 | 310 | 280 |

| 1150 | 300 | 265 |

| 1200 | 300 | 250 |

| 1250 | 300 | 240 |

| 1300 | 300 | 230 |

| 1350 | 300 | 215 |

| 1400 | 300 | 210 |

| 1450 | 300 | 200 |

| 1500 | 300 | 195 |

| 1550 | 300 | 190 |

| 1600 | 300 | 188 |

| 1650 | 300 | 185 |

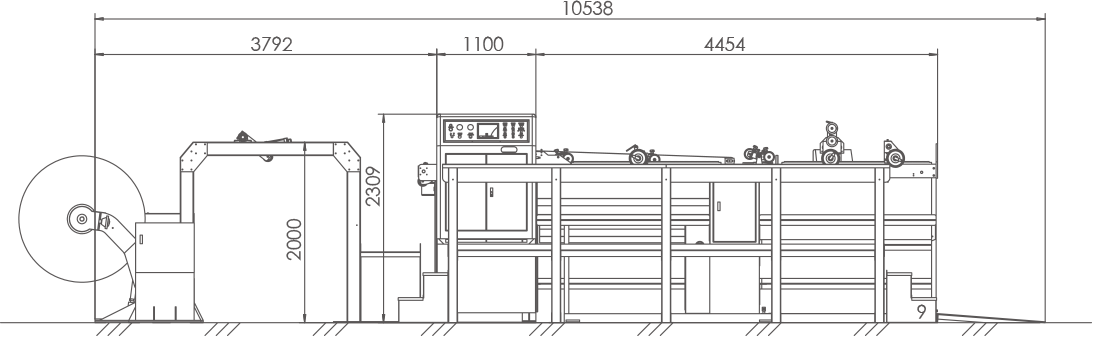

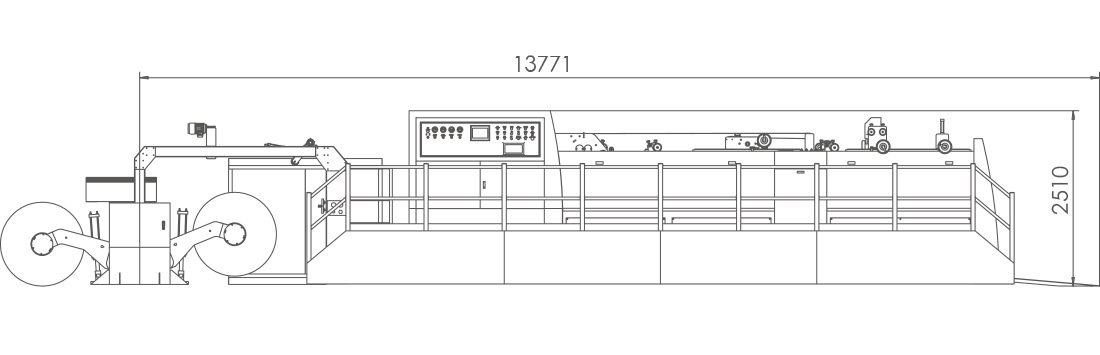

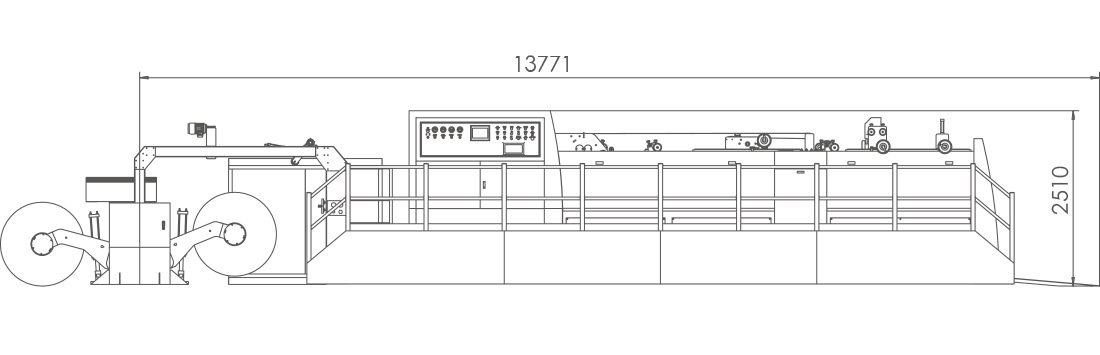

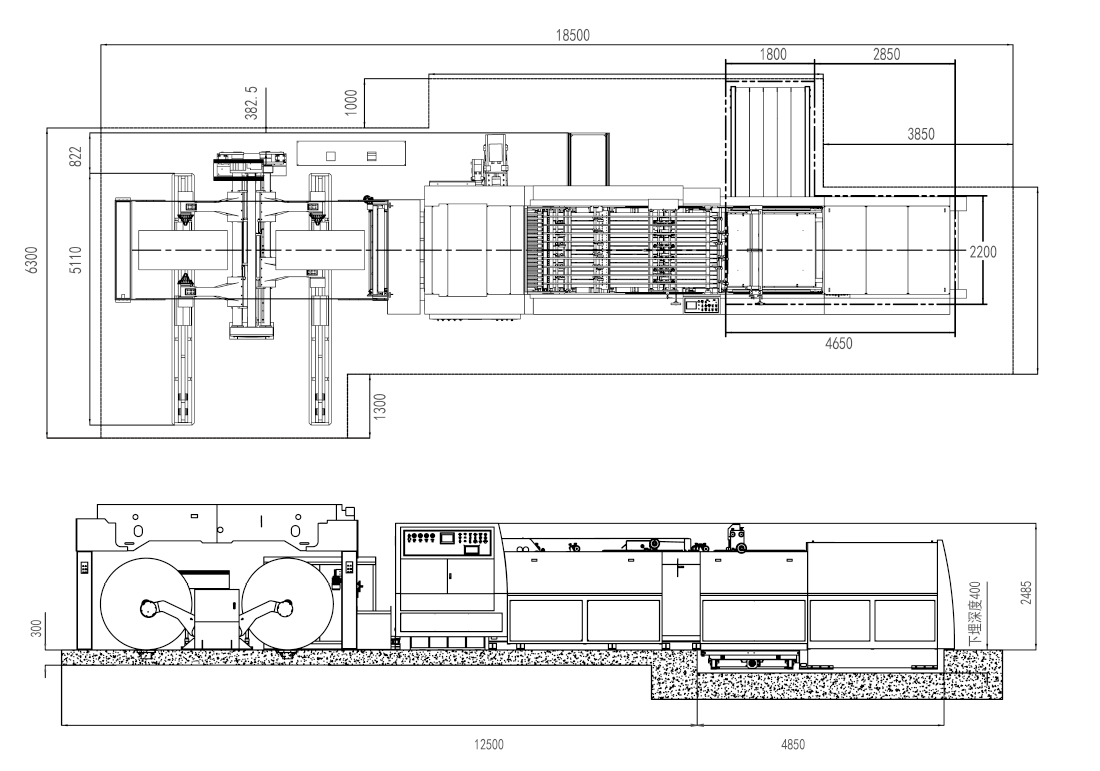

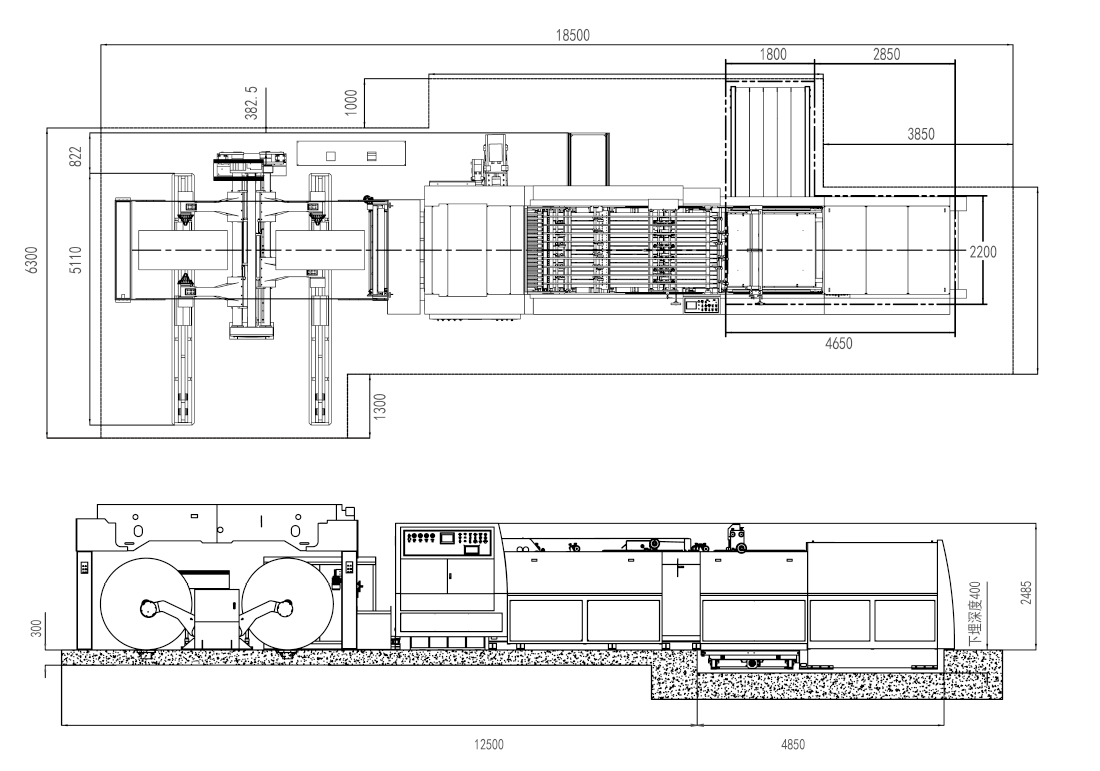

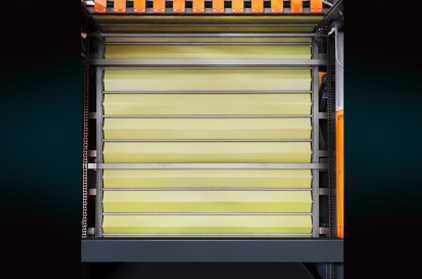

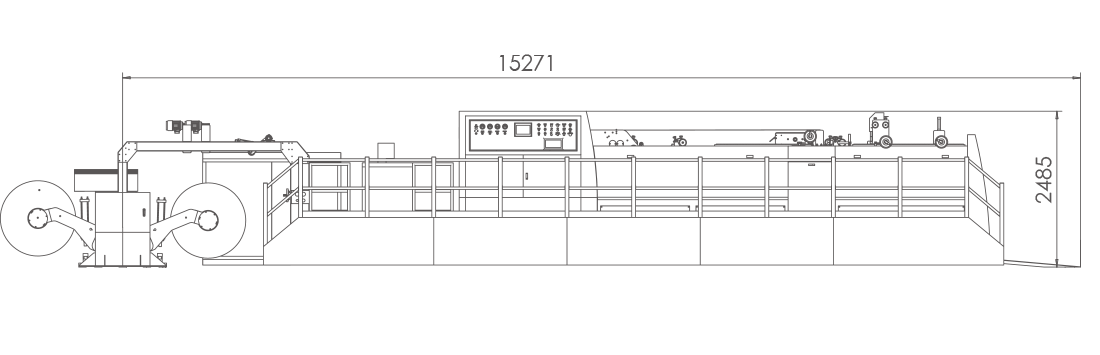

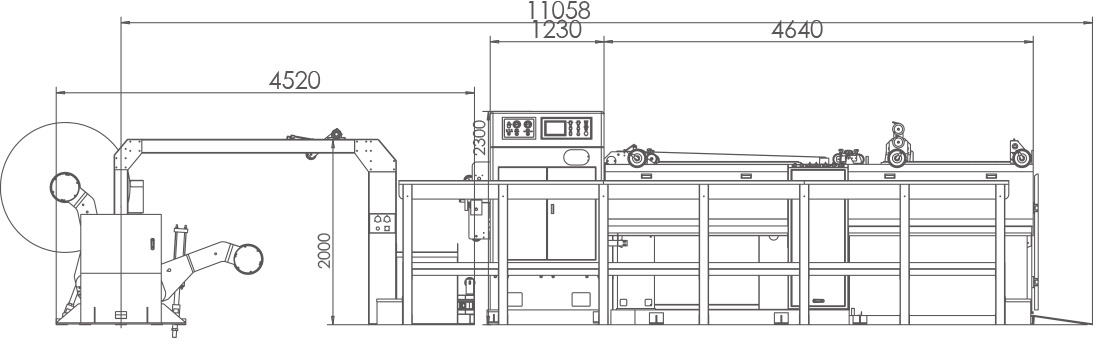

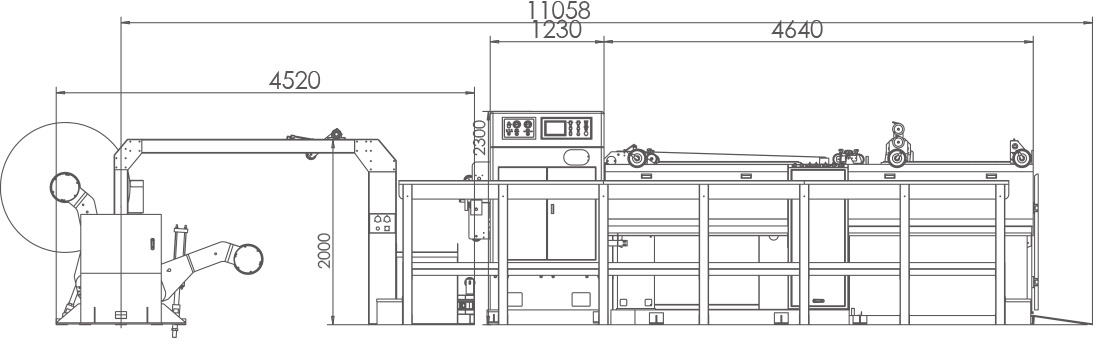

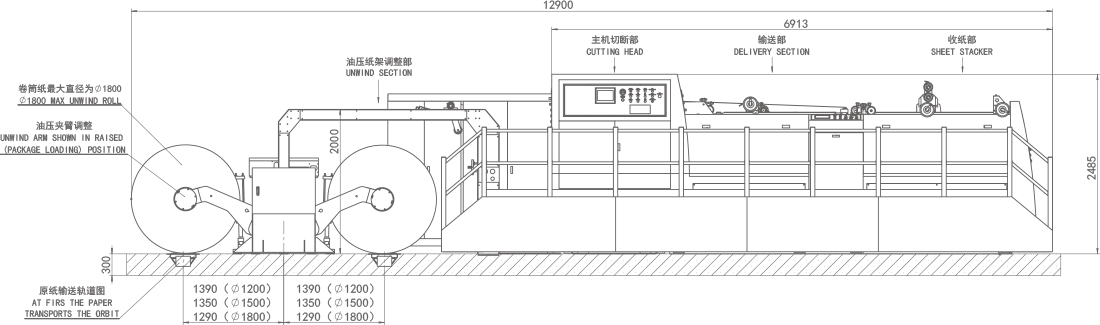

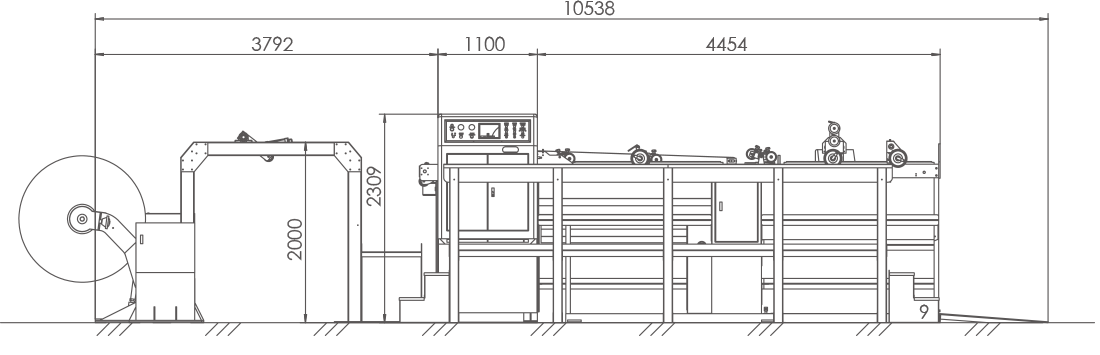

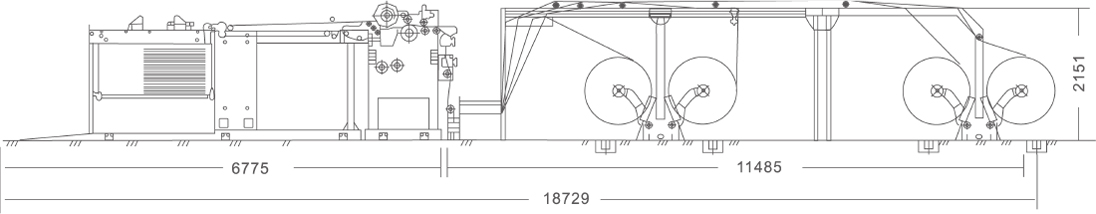

Drawing

Features Introduced

Based on the technology of SM series Servo precision Double-helix High Speed Sheet Cutter Machine,SMC series equipped with more intelligent function and better technological innovation.

- Auto positioning slitting system.

- Paper pre-press device.

- 3 times delivery device(no impression line).

- Collecting board pneumatic lifting device.

Partial Introduction

Auto brake

Auto anti curve

Auto tension control

Auto edge position correction

Auto positioning slitting system (optional)

Paper pre-press device

Double helix knife

Reject gate

Anti-static device

3 times delivery(no impression line)

Collecting board pneumatic lifting device

Siemens plc system

Main Technical Parameter

| Model | SMC-1900 |

| Model of cutting paper | Double rotary sheeter |

| Thickness of cutting paper | 100-1000gsm |

| Cutting length range | 450-1650mm |

| Cutting precision | Cutting length≤1000mm: ±0.1mm Cutting length>1000mm: ±0.1% |

| Max. cutting meter speed | 300 m/min |

| Max. cutting speed | 380 cuts/min |

| Max. scroll diameter | 1800mm |

| Max. paper cutting width | 1900(75”)mm |

| Max. paper piling height | 1600mm |

| The request for air compressor | 0.8Mpa |

| Power consumption | 380V/220VⅩ50Hz |

| Gross weight | 25000kgs |

| Full-load power | 100kw |

| Cutting Length(mm) | Speed(m/min) | Speed(cuts/min) |

| 450 | 100 | 210 |

| 500 | 110 | 220 |

| 550 | 135 | 240 |

| 600 | 155 | 260 |

| 650 | 190 | 290 |

| 700 | 230 | 320 |

| 750 | 290 | 385 |

| 800 | 300 | 380 |

| 850 | 300 | 355 |

| 900 | 300 | 345 |

| 950 | 300 | 320 |

| 1000 | 300 | 300 |

| 1050 | 300 | 285 |

| 1100 | 290 | 265 |

| 1150 | 285 | 250 |

| 1200 | 280 | 235 |

| 1250 | 270 | 220 |

| 1300 | 260 | 210 |

| 1350 | 260 | 195 |

| 1400 | 260 | 190 |

| 1450 | 260 | 180 |

| 1500 | 260 | 175 |

| 1550 | 260 | 168 |

| 1600 | 250 | 160 |

| 1650 | 250 | 155 |

Drawing

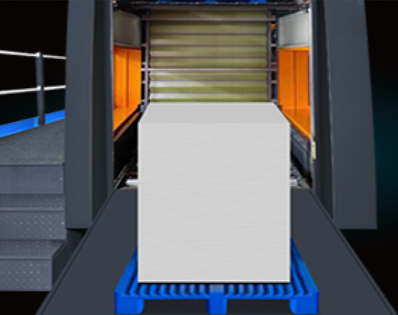

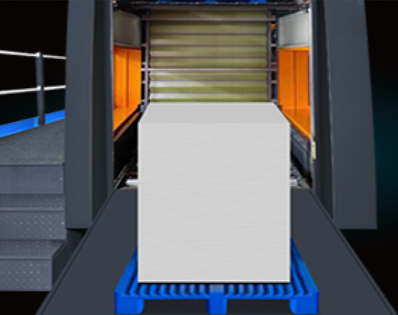

Features Introduced

Based on SMC series Servo precision Double-helix High Speed Sheet Cutter Machine, this machine equipped with automatic splicer and pallet changer, which enable it realizing fully automatic operation, and embodied the intelligent and efficient technical characteristics of the machine.

Partial Introduction

Auto splicer

Auto pallet changer

Auto pallet changer

Auto brake

Auto anti curve

Auto tension control

Auto edge position correction

Auto positioning slitting system (optional)

Paper pre-press device

Double helix knife

Reject gate

Anti-static device

3 times delivery(no impression line)

Collecting board pneumatic lifting device

Siemens plc system

Main Technical Parameter

| Model | SMC-1100ZH/1500ZH/1700ZH |

| Model of cutting paper | Double rotary sheeter |

| Thickness of cutting paper | 100-1000gsm |

| Cutting length range | 450-1650mm |

| Cutting precision | Cutting length≤1000mm: ±0.1mm Cutting length>1000mm: ±0.1% |

| Max. cutting meter speed | 350 m/min |

| Max. cutting speed | 440 cuts/min |

| Max. scroll diameter | 1800mm |

| Max. paper cutting width | 1100ZH(45”)mm 1500ZH(59”)mm 1700ZH(67”)mm |

| Max. paper piling height | 1600mm |

| The request for air compressor | 0.8Mpa |

| Power consumption | 380V/220VⅩ50Hz |

| Gross weight | 25000/27000/30000kgs |

| Full-load power | 69/82/90kw |

| Cutting Length(mm) | Speed(m/min) | Speed(cuts/min) |

| 450 | 125 | 275 |

| 500 | 160 | 315 |

| 550 | 190 | 350 |

| 600 | 210 | 350 |

| 650 | 250 | 380 |

| 700 | 290 | 410 |

| 750 | 330 | 440 |

| 800 | 330 | 410 |

| 850 | 330 | 385 |

| 900 | 330 | 365 |

| 950 | 330 | 350 |

| 1000 | 330 | 330 |

| 1050 | 320 | 300 |

| 1100 | 310 | 280 |

| 1150 | 300 | 265 |

| 1200 | 300 | 250 |

| 1250 | 300 | 240 |

| 1300 | 300 | 230 |

| 1350 | 300 | 215 |

| 1400 | 300 | 210 |

| 1450 | 300 | 200 |

| 1500 | 300 | 195 |

| 1550 | 300 | 190 |

| 1600 | 300 | 188 |

| 1650 | 300 | 185 |

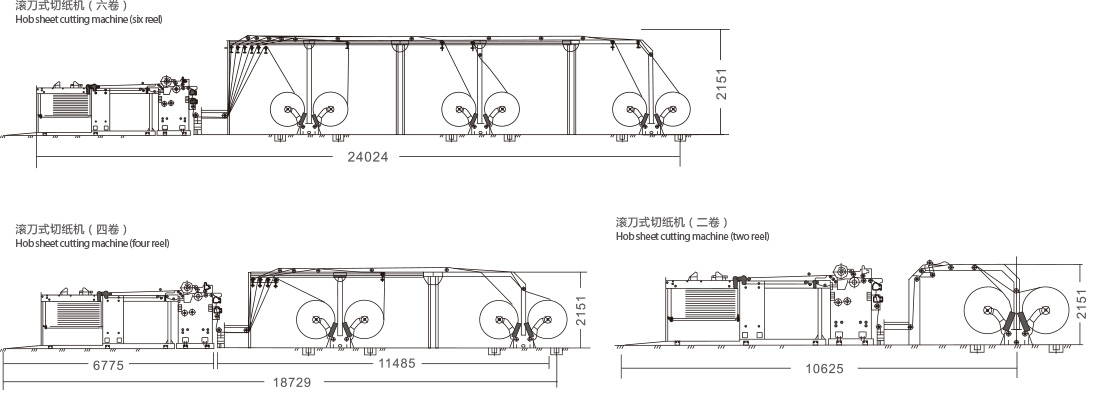

Drawing

Features Introduced

Based on SMC series Servo precision Double-helix High Speed Sheet Cutter Machine, this machine equipped with automatic splicer and pallet changer, which enable it realizing fully automatic operation, and embodied the intelligent and efficient technical characteristics of the machine.

Partial Introduction

Auto splicer

Auto pallet changer

Auto pallet changer

Auto brake

Auto anti curve

Auto tension control

Auto edge position correction

Auto positioning slitting system (optional)

Paper pre-press device

Double helix knife

Reject gate

Anti-static device

3 times delivery(no impression line)

Collecting board pneumatic lifting device

Siemens plc system

Main Technical Parameter

| Model | SMC-1900ZH |

| Model of cutting paper | Double rotary sheeter |

| Thickness of cutting paper | 100-1000gsm |

| Cutting length range | 450-1650mm |

| Cutting precision | Cutting length≤1000mm: ±0.1mm Cutting length>1000mm: ±0.1% |

| Max. cutting meter speed | 300 m/min |

| Max. cutting speed | 380 cuts/min |

| Max. scroll diameter | 1800mm |

| Max. paper cutting width | 1900ZH(75”)mm |

| Max. paper piling height | 1600mm |

| The request for air compressor | 0.8Mpa |

| Power consumption | 380V/220VⅩ50Hz |

| Gross weight | 32000kgs |

| Full-load power | 100kw |

| Cutting Length(mm) | Speed(m/min) | Speed(cuts/min) |

| 450 | 100 | 210 |

| 500 | 110 | 220 |

| 550 | 135 | 240 |

| 600 | 155 | 260 |

| 650 | 190 | 290 |

| 700 | 230 | 320 |

| 750 | 290 | 385 |

| 800 | 300 | 380 |

| 850 | 300 | 355 |

| 900 | 300 | 345 |

| 950 | 300 | 320 |

| 1000 | 300 | 300 |

| 1050 | 300 | 285 |

| 1100 | 290 | 265 |

| 1150 | 285 | 250 |

| 1200 | 280 | 235 |

| 1250 | 270 | 220 |

| 1300 | 260 | 210 |

| 1350 | 260 | 195 |

| 1400 | 260 | 190 |

| 1450 | 260 | 180 |

| 1500 | 260 | 175 |

| 1550 | 260 | 168 |

| 1600 | 250 | 160 |

| 1650 | 250 | 155 |

Drawing

Features Introduced

SMC-1100 Cigarette Packing Servo Precision Double-Helix High Speed Sheet Cutter Machine With Photoelectric Tracking is a high-precision and efficient sheet cutter equipment developed by our company.This machine adopts several edge position correction function,embedded double-helix design, non-stop rolling curtain paper delivery device, is easy to operate.The photoelectric tracking cutting accuracy is within ≤± 0.1mm,the edge of cutting paper is smooth without crude or powder.It is the most ideal photoelectric tracking sheet cutting machine in cigarette packing printing industry at present.

Partial Introduction

Slitting system

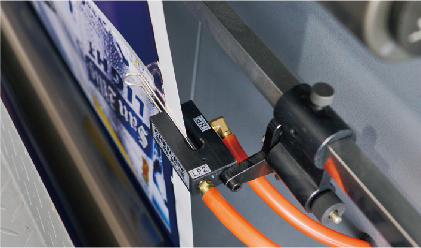

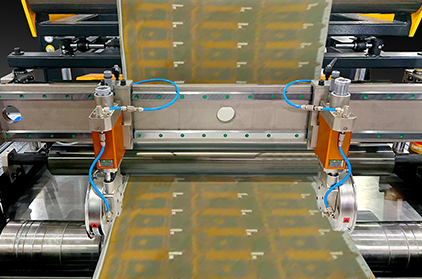

Photoelectric tracking system

3 times delivery (No impression line)

Non-stop rolling curtain paper delivery device

Main Technical Parameter

| Model | SMC-1100 |

| Model of cutting paper | Double rotary sheeter |

| Thickness of cutting paper | 100-800gsm |

| Cutting length range | 450-1450mm |

| Cutting precision | Cutting length≤1000mm: ±0.1mm Cutting length>1000mm: ±0.1% |

| Max. cutting meter speed | 330m/min |

| Max. cutting speed | 540cuts/min |

| Max. photoelectric tracking cutting meter speed | 200m/min |

| Max. photoelectric tracking cutting speed | 200cuts/min |

| Max. scroll diameter | 1800mm |

| Max. paper cutting width | 1100(45”)mm |

| Max. paper piling height | 1400mm |

| The request for air compressor | 0.8Mpa |

| Power consumption | 380V/220V×50Hz |

| G.W. | 18000kgs |

| Full-load Power | 69kw |

| Cutting Length(mm) | Speed(m/min) | Speed(cuts/min) |

| 450 | 195 | 435 |

| 500 | 240 | 480 |

| 600 | 325 | 540 |

| 700 | 330 | 475 |

| 800 | 330 | 410 |

| 900 | 325 | 365 |

| 1000 | 310 | 310 |

| 1100 | 300 | 275 |

| 1200 | 300 | 250 |

| 1300 | 305 | 235 |

| 1400 | 315 | 235 |

| 1500 | 330 | 220 |

| 1600 | 335 | 210 |

Features Introduced

Digital ink-jet printing is a printing type of non-contact, non pressure, non plate printing. All digital information can be printed by inputting the digital ink-jet printer through the interface. The traditional ink-jet printing is printing first, then ink-jet printing, which is low efficiency and large loss in paper. At present,the Digital Ink-jet Double-helix High Speed Sheet Cutter Machine developed by our company is to print QR code, bar code and digital pattern on the jumbo roll first through digital ink-jet,then cut the jumbo roll into single sheets, realizing intelligent and efficient detection, enabling digital ink-jet printing and slitting to be completed at one time, greatly reducing paper loss.

Partial Introduction

Photoelectric tracking system

Digital printing unit

Main Technical Parameter

| Model | SMC-1100S/1500S/1700S |

| Model of cutting paper | Double rotary sheeter |

| Thickness of cutting paper | 100-1000gsm |

| Cutting length range | 450-1650mm |

| Cutting precision | Cutting length≤1000mm: ±0.1mm Cutting length>1000mm: ±0.1% |

| Max. cutting meter speed | 350 m/min |

| Max. cutting speed | 440 cuts/min |

| Max. digit printing speed | 150 m/min |

| Max. scroll diameter | 1800mm |

| Max. paper cutting width | 1100S(45”)mm 1500S(59”)mm 1700S(67”)mm |

| Max. paper piling height | 1600mm |

| The request for air compressor | 0.8Mpa |

| Power consumption | 380V/220VⅩ50Hz |

| Gross weight | 21000/23000/26000kgs |

| Full-load power | 69/82/90kw |

| Cutting Length(mm) | Speed(m/min) | Speed(cuts/min) |

| 450 | 125 | 275 |

| 500 | 160 | 315 |

| 550 | 190 | 350 |

| 600 | 210 | 350 |

| 650 | 250 | 380 |

| 700 | 290 | 410 |

| 750 | 330 | 440 |

| 800 | 330 | 410 |

| 850 | 330 | 385 |

| 900 | 330 | 365 |

| 950 | 330 | 350 |

| 1000 | 330 | 330 |

| 1050 | 320 | 300 |

| 1100 | 310 | 280 |

| 1150 | 300 | 265 |

| 1200 | 300 | 250 |

| 1250 | 300 | 240 |

| 1300 | 300 | 230 |

| 1350 | 300 | 215 |

| 1400 | 300 | 210 |

| 1450 | 300 | 200 |

| 1500 | 300 | 195 |

| 1550 | 300 | 190 |

| 1600 | 300 | 188 |

| 1650 | 300 | 185 |

Drawing

Features Introduced

Digital ink-jet printing is a printing type of non-contact, non pressure, non plate printing. All digital information can be printed by inputting the digital ink-jet printer through the interface. The traditional ink-jet printing is printing first, then ink-jet printing, which is low efficiency and large loss in paper. At present,the Digital Ink-jet Double-helix High Speed Sheet Cutter Machine developed by our company is to print QR code, bar code and digital pattern on the jumbo roll first through digital ink-jet,then cut the jumbo roll into single sheets, realizing intelligent and efficient detection, enabling digital ink-jet printing and slitting to be completed at one time, greatly reducing paper loss.

Partial Introduction

Photoelectric tracking system

Digital printing unit

Main Technical Parameter

| Model | SMC-1900S |

| Model of cutting paper | Double rotary sheeter |

| Thickness of cutting paper | 100-1000gsm |

| Cutting length range | 450-1650mm |

| Cutting precision | Cutting length≤1000mm: ±0.1mm Cutting length>1000mm: ±0.1% |

| Max. cutting meter speed | 300 m/min |

| Max. cutting speed | 380 cuts/min |

| Max. digit printing speed | 150 m/min |

| Max. scroll diameter | 1800mm |

| Max. paper cutting width | 1900S(75”)mm |

| Max. paper piling height | 1600mm |

| The request for air compressor | 0.8Mpa |

| Power consumption | 380V/220VⅩ50Hz |

| Gross weight | 28000kgs |

| Full-load power | 100kw |

| Cutting Length(mm) | Speed(m/min) | Speed(cuts/min) |

| 450 | 100 | 210 |

| 500 | 110 | 220 |

| 550 | 135 | 240 |

| 600 | 155 | 260 |

| 650 | 190 | 290 |

| 700 | 230 | 320 |

| 750 | 290 | 385 |

| 800 | 300 | 380 |

| 850 | 300 | 355 |

| 900 | 300 | 345 |

| 950 | 300 | 320 |

| 1000 | 300 | 300 |

| 1050 | 300 | 285 |

| 1100 | 290 | 265 |

| 1150 | 285 | 250 |

| 1200 | 280 | 235 |

| 1250 | 270 | 220 |

| 1300 | 260 | 210 |

| 1350 | 260 | 195 |

| 1400 | 260 | 190 |

| 1450 | 260 | 180 |

| 1500 | 260 | 175 |

| 1550 | 260 | 168 |

| 1600 | 250 | 160 |

| 1650 | 250 | 155 |

Drawing

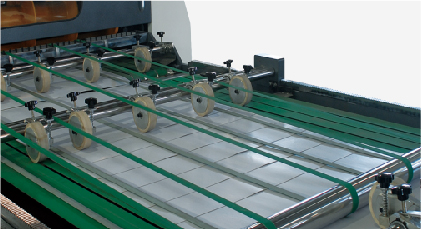

Features Introduced

SM-1100/1500/1700 Servo Precision Double-Helix High Speed Sheet Cutter Machine apply the advanced technique of Germany and Italy, combining with the rich experience and leading manufacturing techniques of our senior engineers to build and launch a new generation of sheet cutter equipment. This machine adopts double-helix design, the edge of cutting paper is smooth without crude or powder, what’s more, with the feature of high cutting precision makes sure paper after cutting can be directly used on printing machines, which help to reduces the production cost and improve production efficiency. It is the most popular and ideal cutting machine in paper making and printing industry at present.

Partial Introduction

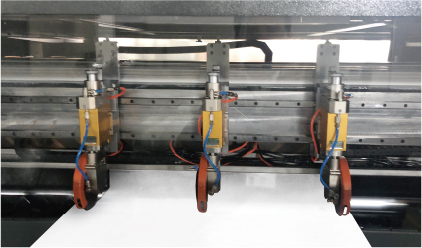

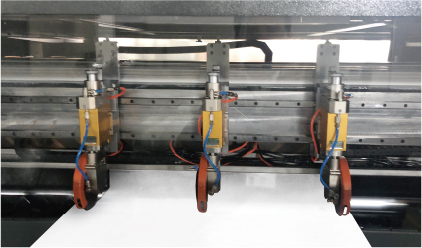

Three sets of slitting knife are used for trimming and middle slitting

Conveying unit

Main Technical Parameter

| Model | SM-1100/1500/1700 |

| Model of cutting paper | Double rotary sheeter |

| Thickness of cutting paper | 100-1000gsm |

| Cutting length range | 450-1650mm |

| Cutting precision | Cutting length≤1000mm: ±0.2mm Cutting length>1000mm: ±0.1% |

| Max. cutting meter speed | 350 m/min |

| Max. cutting speed | 440 cuts/min |

| Max. scroll diameter | 1800mm |

| Max. paper cutting width | 1100(45”)mm 1500(59”)mm 1700(67”)mm |

| Max. paper piling height | 1600mm |

| The request for air compressor | 0.8Mpa |

| Power consumption | 380V/220VⅩ50Hz |

| Gross weight | 16000/18000/20000kgs |

| Full-load power | 69/82/90kw |

| Cutting Length(mm) | Speed(m/min) | Speed(cuts/min) |

| 450 | 125 | 275 |

| 500 | 160 | 315 |

| 550 | 190 | 350 |

| 600 | 210 | 350 |

| 650 | 250 | 380 |

| 700 | 290 | 410 |

| 750 | 330 | 440 |

| 800 | 330 | 410 |

| 850 | 330 | 385 |

| 900 | 330 | 365 |

| 950 | 330 | 350 |

| 1000 | 330 | 330 |

| 1050 | 320 | 300 |

| 1100 | 310 | 280 |

| 1150 | 300 | 265 |

| 1200 | 300 | 250 |

| 1250 | 300 | 240 |

| 1300 | 300 | 230 |

| 1350 | 300 | 215 |

| 1400 | 300 | 210 |

| 1450 | 300 | 200 |

| 1500 | 300 | 195 |

| 1550 | 300 | 190 |

| 1600 | 300 | 188 |

| 1650 | 300 | 185 |

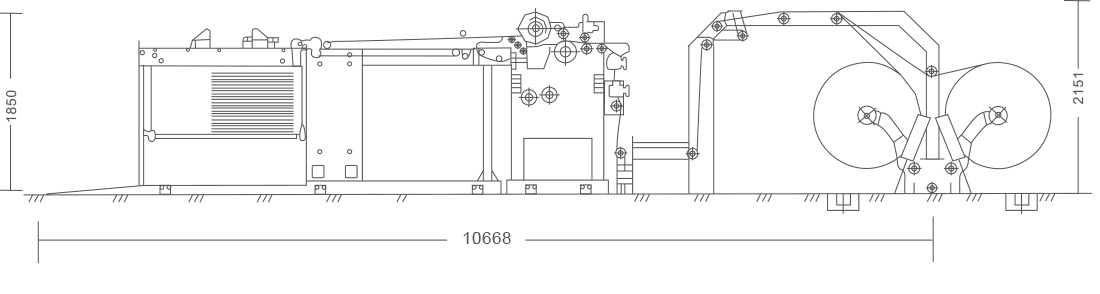

Drawing

Features Introduced

SM-1900 Servo Precision Double-Helix High Speed Sheet Cutter Machine apply the advanced technique of Germany and Italy, combining with the rich experience and leading manufacturing techniques of our senior engineers to build and launch a new generation of sheet cutter equipment. This machine adopts double-helix design, the edge of cutting paper is smooth without crude or powder, what’s more, with the feature of high cutting precision makes sure paper after cutting can be directly used on printing machines, which help to reduces the production cost and improve production efficiency. It is the most popular and ideal cutting machine in paper making and printing industry at present.

Partial Introduction

Three sets of slitting knife are used for trimming and middle slitting

Conveying unit

Main Technical Parameter

| Model | SM-1900 |

| Model of cutting paper | Double rotary sheeter |

| Thickness of cutting paper | 100-1000gsm |

| Cutting length range | 450-1650mm |

| Cutting precision | Cutting length≤1000mm: ±0.2mm Cutting length>1000mm: ±0.1% |

| Max. cutting meter speed | 300 m/min |

| Max. cutting speed | 380 cuts/min |

| Max. scroll diameter | 1800mm |

| Max. paper cutting width | 1900(75”)mm |

| Max. paper piling height | 1600mm |

| The request for air compressor | 0.8Mpa |

| Power consumption | 380V/220VⅩ50Hz |

| Gross weight | 22000kgs |

| Full-load power | 100kw |

| Cutting Length(mm) | Speed(m/min) | Speed(cuts/min) |

| 450 | 100 | 210 |

| 500 | 110 | 220 |

| 550 | 135 | 240 |

| 600 | 155 | 260 |

| 650 | 190 | 290 |

| 700 | 230 | 320 |

| 750 | 290 | 385 |

| 800 | 300 | 380 |

| 850 | 300 | 355 |

| 900 | 300 | 345 |

| 950 | 300 | 320 |

| 1000 | 300 | 300 |

| 1050 | 300 | 285 |

| 1100 | 290 | 265 |

| 1150 | 285 | 250 |

| 1200 | 280 | 235 |

| 1250 | 270 | 220 |

| 1300 | 260 | 210 |

| 1350 | 260 | 195 |

| 1400 | 260 | 190 |

| 1450 | 260 | 180 |

| 1500 | 260 | 175 |

| 1550 | 260 | 168 |

| 1600 | 250 | 160 |

| 1650 | 250 | 155 |

Drawing

Features Introduced

KM-1100/1500/1700 Servo Precision Double-Helix High Speed Sheet Cutter Machine adopts double-helix design, the edge of cutting paper is smooth without crude or powder, what’s more, with the feature of high cutting precision makes sure paper after cutting can be directly used on printing machines, which help to reduces the production cost and improve production efficiency. lt is the most popular and ideal cutting machine in paper making and printing industry at present.

Partial Introduction

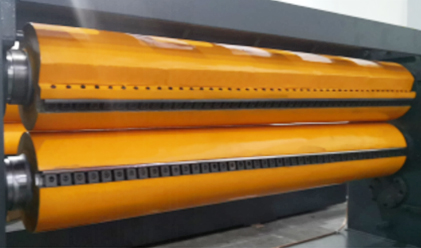

Embedded double helix knife (Invention patent)

Slitting knifes (Optional)

Conveying unit

Main Technical Parameter

| Model | KM-1100/1500/1700 |

| Model of cutting paper | Double rotary sheeter |

| Thickness of cutting paper | 100-800gsm |

| Cutting length range | 450-1650mm |

| Cutting precision (1 roll) | Cutting length≤1000mm: ±0.1mm Cutting length>1000mm: ±0.1% |

| Max. cutting meter speed | 330m/min |

| Max. cutting speed | 540cuts/min |

| Max. scroll diameter | 1500mm(KM-1100) 1800mm(KM-1500/1700) |

| Max. paper cutting width | 1100(45”)mm 1500(59”)mm 1700(67”)mm |

| Max. paper piling height | 1300mm(KM-1100) 1500mm(KM-1500/1700) |

| The request for air compressor | 0.8Mpa |

| Power consumption | 380V/220V×50Hz |

| G.W. (1 roll) | 16000/18000/21000kgs |

| Full-load Power | 69/82/90kw |

| Cutting Length(mm) | Speed(m/min) | Speed(cuts/min) |

| 450 | 195 | 435 |

| 500 | 240 | 480 |

| 600 | 325 | 540 |

| 700 | 330 | 475 |

| 800 | 330 | 410 |

| 900 | 325 | 365 |

| 1000 | 310 | 310 |

| 1100 | 300 | 275 |

| 1200 | 300 | 250 |

| 1300 | 305 | 235 |

| 1400 | 315 | 235 |

| 1500 | 330 | 220 |

| 1600 | 335 | 210 |

| 1650 | 335 | 210 |

Drawing

Features Introduced

GM-1100/1500/1700/1900 Servo Precision High Speed Sheet Cutter apply the advanced techinque of Germany and England. The machine computer control system apply servo motor and AC transducer which are both international of top brand. The conveyer belt apply NITTA from Japan. The pneumatic vibrator apply FINDEVA from Switzerland. The electrical system adopts MOELLER&OMRON. The speed of cutting paper is so fast and stable. Germany precise bearing and cutting knife assure the high cutting precision. The touchscreen makes the operation easy. The anti-curve rack assurethe paper flat. This machine is the paper processing machine which is very popular in the paper making and printing industry. It can improve the efficiency and benifit of your work.

Partial Introduction

Three sets of slitting knife are used for trimming and middle slitting

Cutting knife unit

Overlapping unit

Electric appliance unit

Main Technical Parameter

| Model | GM-1100/1500/1700/1900 |

| Model of cutting paper | The up knife cut reciprocally and the down knife is fixed |

| Thickness of cutting paper | 60-550g |

| Max. scroll diameter | 1800mm |

| Max. paper cutting width | 1100mm/1500mm/1700mm/1900mm |

| Cutting length range | 450-1600mm |

| The format of slitting | 2 sheet |

| Cutting precision | Cutting length≤1000mm: +/-0.5mm; Cutting length>1000mm: +/-0.1% |

| Max. cutting speed | 350cuts/min |

| Max. cutting meter speed | 350m/min |

| Max. paper piling height | 1500mm |

| The request for air compressor | 0.8Mpa |

| Power consumption | 380V/220V×50Hz |

| Gross weight | 11000kgs/13000kgs/15000kgs/17000kgs |

| Full-load Power | 22/26/30/35kw |

| High-precision single knife cutting machine | 1SET |

| Paper prismatic automatic adjustment system | 1SET |

| Equipment of electrostatic elimination | 1SET |

| Middle slitting and waste collection system | 1SET |

| Automatic counting and label inserting equipment | 1SET |

| Paper transporting equipment | 1SET |

| Automatic paper trimming and collecting machine | 1SET |

| Electrical controlling system | 1SET |

| Driving motor system | 1SET |

| Accessory by machine | 1SET |

| Double arm oil pressure shaftless mill roll stand | 1SET |

| Automatic directing and paper tension controller | 1SET |

| Equipment of automatic vacuum | 1SET |

| Operation system:LCD panel by operator | 1SET |

| Main drive system:AC servo motor | 1SET |

Our company reserves the right to change technical parameter without futher notice.

Drawing

Features Introduced

CM-1100/1500/1700/1900A Servo Precision Sheet Cutter apply the advanced technique of Germany and England. The computer control system apply AC servo motor and AC transducer. The conveyer belt apply NITTA from Japan. The pneumatic vibrator apply FINOLEVA from Switzerland. The electrical system adopts MOELLER&OMRON, the speed of cutting paper is fast and stable. Germany precise bearing and cutting knife assure the high cutting precision. The touch screen makes the operation easy. The anticurve rack assures the paper flat. The machine is very popular in the paper making and printing industry.

Partial Introduction

Paper rack stand and brake equipment

Automatic anti-curve equipment

Automatic stacker

Main Technical Parameter

| Model | CM-1100/1500/1700/1900A |

| Model of cutting paper | The up knife cut reciprocally and the down knife is fixed |

| Thickness of cutting paper | 60-550g |

| Max. scroll diameter | 1800mm |

| Max. paper cutting width | 1100mm/1500mm/1700mm/1900mm |

| Cutting length range | 450-1600mm |

| The format of slitting | 2 sheet |

| Cutting precision | Cutting length≤1000mm: +/-0.5mm; Cutting length>1000mm: +/-0.1% |

| Max. cutting speed | 300cuts/min |

| Max. cutting meter speed | 300m/min |

| Max. paper piling height | 1500mm |

| The request for air compressor | 0.8Mpa |

| Power consumption | 380V/220V×50Hz |

| Gross weight | 9000kgs/11000kgs/13000kgs/15000kgs |

| Full-load Power | 22/26/30/35kw |

| High-precision single knife cutting machine | 1SET |

| Paper prismatic automatic adjustment system | 1SET |

| Paper transporting equipment | 1SET |

| Middle slitting and waste collection system | 1SET |

| Electrical controlling system | 1SET |

| Driving motor system | 1SET |

| Accessory by machine | 1SET |

| Operation system:LCD panel by operator | 1SET |

| Main drive system:AC servo motor | 1SET |

Our company reserves the right to change technical parameter without futher notice.

Drawing

Partial Introduction

Paper feeding unit

Electric appliance unit

Overlapping unit

Single sheet outlet can be adjusted by the overlapping unit.

The number of overlapping sheet can be adjusted by the overapping unit.

Main Technical Parameter

| Model | CM-1100/1500/1700/1900A |

| Model of cutting paper | The up knife cut reciprocally and the down knife is fixed |

| Thickness of cutting paper | 60-550g |

| Max. scroll diameter | 1800mm |

| Max. paper cutting width | 1100mm/1500mm/1700mm/1900mm |

| Cutting length range | 450-1600mm |

| The format of slitting | 2 sheet |

| Cutting precision | Cutting length≤1000mm: +/-0.5mm, Cutting length>1000mm: +/-0.1% |

| Max. cutting speed | 300cuts/min |

| Max. cutting meter speed | 300m/min |

| Max. paper piling height | 1500mm |

| The request for air compressor | 0.8Mpa |

| Power consumption | 380V/220V×50Hz |

| Gross weight | 9000kgs/11000kgs/13000kgs/15000kgs |

| Full-load power | 22/26/30/35kw |

| High-precision single knife cutting machine | 1SET |

| Paper prismatic automatic adjustment system | 1SET |

| Paper transporting equipment | 1SET |

| Middle slitting and waste collection system | 1SET |

| Electrical controlling system | 1SET |

| Driving motor system | 1SET |

| Accessory by machine | 1SET |

| Operation system:LCD panel by operator | 1SET |

| Main drive system:AC servo motor | 1SET |

Our company reserves the right to change technical parameter without futher notice.

Drawing

Partial Introduction

Paper rack stand

Automatic anti-curve equipment

Automatic stacker

Main Technical Parameter

| Model | CM-1100/1500/1700/1900A |

| Model of cutting paper | The up knife cut reciprocally and the down knife is fixed |

| Thickness of cutting paper | 60-550g |

| Max. scroll diameter | 1800mm |

| Max. paper cutting width | 1100mm/1500mm/1700mm/1900mm |

| Cutting length range | 450-1600mm |

| The format of slitting | 2 sheet |

| Cutting precision | Cutting length≤1000mm: +/-0.5mm, Cutting length>1000mm: +/-0.1% |

| Max. cutting speed | 300cuts/min |

| Max. cutting meter speed | 300m/min |

| Max. paper piling height | 1500mm |

| The request for air compressor | 0.8Mpa |

| Power consumption | 380V/220V×50Hz |

| Gross weight | 9000kgs/11000kgs/13000kgs/15000kgs |

| Full-load Power | 22/26/30/35kw |

| High-precision single knife cutting machine | 1SET |

| Paper prismatic automatic adjustment system | 1SET |

| Paper transporting equipment | 1SET |

| Middle slitting and waste collection system | 1SET |

| Electrical controlling system | 1SET |

| Driving motor system | 1SET |

| Accessory by machine | 1SET |

| Operation system:LCD panel by operator | 1SET |

| Main drive system:AC servo motor | 1SET |

Our company reserves the right to change technical parameter without futher notice.

Drawing

Partial Introduction

Photoelectric tracking system

Edge posltion controller system

Fast sheet cutter

Main Technical Parameter

| Model | CM-1100/1500/1700/1900A |

| Model of cutting paper | The up knife cut reciprocally and the down knife is fixed |

| Thickness of cutting paper | 60-550g |

| Max. scroll diameter | 1800mm |

| Max. paper cutting width | 1100mm/1500mm/1700mm/1900mm |

| Cutting length range | 450-1600mm |

| The format of slitting | 2 sheet |

| Cutting precision | Cutting length≤1000mm: +/-0.5mm; Cutting length>1000mm: +/-0.1% |

| Max. cutting speed | 300cuts/min |

| Max. cutting meter speed | 300m/min |

| Max. paper piling height | 1500mm |

| The request for air compressor | 0.8Mpa |

| Power consumption | 380V/220V×50Hz |

| Gross weight | 9000kgs/11000kgs/13000kgs/15000kgs |

| Full-load Power | 22/26/30/35kw |

| High-precision single knife cutting machine | 1SET |

| Paper prismatic automatic adjustment system | 1SET |

| Paper transporting equipment | 1SET |

| Middle slitting and waste collection system | 1SET |

| Electrical controlling system | 1SET |

| Driving motor system | 1SET |

| Accessory by machine | 1SET |

| Operation system:LCD panel by operator | 1SET |

| Main drive system:AC servo motor | 1SET |

Our company reserves the right to change technical parameter without futher notice.

Drawing